Soundproofing Interior Walls

dB-Bloc is a versatile and effective material used for soundproofing and sound attenuation in walls and ceiling structures. It’s commonly used to reduce the transmission of airborne and impact noise, making it a popular choice in both residential and commercial applications. The key principle behind dB-Bloc’s effectiveness lies in its mass and its ability to disrupt sound waves by decoupling a vibrating surface from the structure to which it is attached. The density of dB-Bloc will impede vibrations and lower the level of sound energy that is able to transfer through your common surface to an adjoining space.

Questions? Call 1-800-638-9355

Mass & Damping of dB-Bloc

The high mass of dB-Bloc contributes to its soundproofing capabilities. Sound is a form of energy that travels through vibrations in the air or materials. When sound waves encounter the mass of dB-Bloc, they are absorbed and converted into small amounts of heat due to the material’s internal damping properties. This conversion of sound energy into heat reduces the sound’s intensity & prevents it from passing through the material.

The goal is to embed the density of this material into a layering system that will include a disconnection in your wall or ceiling assembly. The interior wall soundproofing treatment applies to new build, remodel, or existing finished wall or ceiling surfaces. The density of dB-Bloc will force the collapse of vibration, much like placing the flat of your hand on a tuning fork, a wine glass, a guitar string or the face of a drum. If the object can’t vibrate, it can’t conduct and pass sound waves. For more information on your dB-Bloc application, check these links:

See Wall Treatment See Ceiling Treatment

Pricing

dB-Bloc is shipped in 54” x 30’ rolls. Each roll will weigh 150 pounds and cover 135 square feet. Orders can be placed online using the link to the left or by phone to 1-800-638-9355.

Order By PhoneHow to Soundproof a Wall

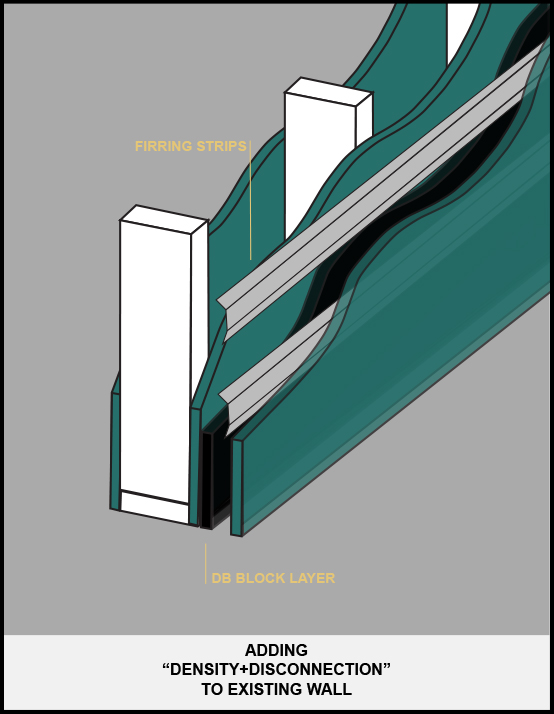

Note that the dB-Bloc sound barrier membrane is only part of the equation. The remainder of your acoustical treatment should include the disconnection of your framing system, as we outline in our Wall and Ceiling sections of this website. For existing walls, the steps are simple:

- Staple dB-Bloc to your wall

- Add a channel system

- Anchor drywall to the channel

- Bonus: Fill the space between the dB-Bloc & final layer of drywall with fiberglass insulation. This reduces resonance in the air cavity and eliminates the triple-leaf effect.

The illustration shown here shows the channels separating your finished drywall layer from the framing structure. See the Demo below. A popular technique for your channels is to start with our RSIC Clips and anchor those to your wall once the dB-Bloc is in place. Then snap hat channels into the clips and finish with drywall.

See RSIC Clips

For New Build or Remodel Walls:

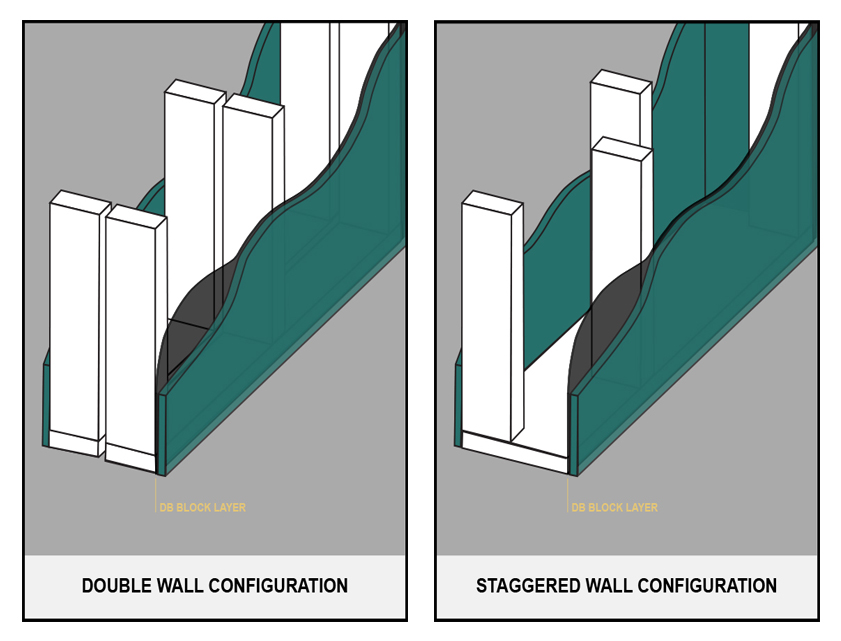

Notice the difference in our disconnection techniques. If you double wall or stagger stud your framing, it negates your need for isolating your assembly with a channel system or the RSIC Clips. Either of these building techniques is separating the rooms that would otherwise be conjoined by the framing system. Simply add the density of dB-Bloc to either of these disconnecting techniques, and you’ve got the collapse in the transmitting sound wave that you need.

Questions? Call 1-800-638-9355

Sound Test Results

Field Test Results include framing + 5/8″ drywall both sides + dB-Bloc + channel system

Test results available upon request.

Your Value Back

A properly installed dB-Bloc soundproofing treatment can take an average STC rated wall of 38-40, and deliver back an STC rated wall of 55-60 or stronger, which is luxury grade soundproofing as rated by the US Government. Leakage of course will decay all results on all projects no matter what. Any common surface that shares electrical, plumbing, ventilation, adjacent untreated walls, floors, ceilings, windows, hallways, stairwells, doors, and more will combine to leak noise. While there is no complete “cure” to sound isolating one room’s noise from the next, there is certainly better “control” you can deliver over your environment using this dB-Bloc material. On average, our interior wall sound insulation can deliver a 10-12 dB drop, but results will vary on every application, with no guarantee of a specific noise reduction value generated. Care must be given to explore all other paths, structure-borne or airborne, that the leaking noise might be taking.

Sound Chamber

Shipping dB-Bloc

dB-Bloc is shipped in 54″ x 30′ rolls. Each roll will cover 135 sq ft and weigh nearly 150 pounds with the core. The density is what makes the treatment perform, but also makes the shipping heavy. Care should be given as to how you will accept the order. Most clients opt for a lift gate that lets the pallet be lowered to the ground. Please inspect the order upon delivery and sign for anything that may have been damaged in transit. For questions related to your shipment, call our help desk at 1-800-638-9355.

Shipping/Receiving Terms & Conditions

Contractor's Corner

Contractor’s Corner

If you are a contractor that has discovered the art of soundproofing a common surface with the use of our dB-Bloc layering sequence, we welcome you to our family of builders who know how to do it right. For you, we offer a free newsletter that delivers timely and helpful insights into the art of combating sound bleed through common wall or floor/ceiling assemblies. Sign up today and help spread our dB-Bloc treatments to future clients of yours!

Soundproofing Walls Q&A

What is dB-Bloc?

dB-Bloc is a versatile and effective material used for soundproofing and sound attenuation in walls and other structures. It’s commonly used to reduce the transmission of airborne and impact noise, making it a popular choice in both residential and commercial applications. The key principle behind MLV’s effectiveness lies in its mass and its ability to disrupt sound waves.

Why do I need it?

Without the density of dB-Bloc, your surfaces are able to accept vibration and pass along the sound wave. Adding dB-Bloc to your surface is equal to placing the flat of your hand on a tuning fork. This dampens the vibration which converts into sound energy. Layering dB-Bloc to your wall or ceiling surface serves the same purpose.

How does it work?

Most common walls are built with a single frame and drywall on both sides. When sound is produced in room A, the sound waves hit the common surface, convert to structure born vibrations, pass through the framing, and release on the other side. Much like a string pulled tight between two coffee cans, the framing in your wall is conducting vibrations. By layering dB-Bloc it acts as a disconnection in your assembly, forcing the collapse of the vibration and protecting the adjoining room from the noise source.

Why does it work?

Once your surface receives the dB-Bloc treatment, the sound wave is no longer able to freely transmit from room to room through structure born vibrations. Up to 90% of your sound bleed can now collapse inside the assembly you have created, rather than pass through to the adjoining room.

How much noise does it block?

There’s a measuring standard in the sound business called an STC value. This stands for Sound Transmission Classification. A standard wall with framing and drywall on both sides, will carry an STC of 33-35. On the STC scale, government standards for a “luxury” rated wall will build to an STC level of 55+. Once you apply the dB-Bloc layering treatment to your common surface, our goal with your project is to deliver this luxury grade rating. If you hit an STC of 55+, you are forcing the collapse of up to 90% of your unwanted noise transmission.

What are Flanking Paths?

Flanking paths are leakage points that will decay your values back. Every room, every wall, every ceiling, will have them. From doors, windows, outlets plates, supply/return vents, plumbing fixtures and more, there will be air pockets that bleed noise regardless of your best efforts to block it. Also, the invisible flanking paths are all the structural connection points that will deliver vibrations up, down, over and around your treatment. Common floor slabs, ceiling structures, and perimeter walls that you choose to not layer with dB-Bloc can all transmit energy around your dB-Bloc treatment. Flanking paths are the reason that no sound barrier treatment will block 100% of your noise, but we can get you close!

Do I need resilient channels?

Unless you have a double wall, a disconnected structure already, or a staggered stud wall, the answer is yes. You need to force a break in the contact points between the adjoining rooms. NetWell offers RSIC Clips if you are interested in the upgrade, otherwise, a standard set of resilient channels will work fine.

What if my walls are finished?

Most of our clients are indeed retrofitting to an existing finished wall or ceiling assembly. Simply staple the dB-Bloc into place, add your resilient channel system, and then a new layer of 5/8” drywall. Adding a layer of fiberglass insulation between the dB-Bloc treatment and the final layer of 5/8″ drywall will reduce resonance in the air cavity and avoid the triple leaf effect.

Does it work on a ceiling?

Yes. Use the same layering sequence as walls – anchor dB-Bloc to your ceiling, add a channel system and/or our RSIC Clips, and a new layer of 5/8” drywall. Fill the air gap between the dB-Bloc & final layer of drywall with fiberglass insulation.

Does it work on a floor?

Yes, but note that we do offer a flooring underlayment called FloorFighter that we recommend you substitute in place of dB-Bloc. FloorFighter carries the same level of density but also has more of a cushioning effect to decouple foot noise.

How much coverage do I need?

dB-Bloc should cover 100% of a common surface. Note that where ever you opt to not layer in the treatment, that becomes the path of least resistance where the sound waves will pass through your assembly and decay your values back.

How do I order it?

You can order dB-Bloc right here on our website, or by phone to 1-800-638-9355. We ship the material in 54” x 30’ rolls to cover 135 sq ft per roll.

How long does it take to get?

dB-Bloc is typically a stock item ready to ship within 24 hours of your order.