Industrial Sound Mitigation and Noise Control

Industrial sound attenuation is all about protection. Noise pollution can easily build to excessive levels of exposure in factory and manufacturing environments, threatening hearing loss, worker productivity, product quality, absenteeism, and turnover. Ignoring the noise levels can prove costly to the business while reducing the noise levels can prove to be a great benefit to both the health of the business as well as the health of the employee. There are 3 stages to industrial sound dampening: Enclose. Isolate. Absorb.

1. Enclose Your Machines

The first goal of your noise attenuation project should be to identify any noise sources that you are able to enclose. Using our sound control blankets, shutting the noise down at the source will produce the most aggressive and cost-effective results. We realize this is not always practical, for example, how do you enclose a noisy forklift? But for stationary noise sources such as compressors, grinders, pumps, presses, & other manufacturing equipment, this should be step 1 in your quest to lower noise level exposures. NetWell’s Full & Partial Acoustic Enclosures are an effective solution to block sound from escaping the area surrounding loud machinery, yet still allows operators to gain access to the equipment. Industrial noise control is always a step-through staging process as there are a variety of noise sources that combine to contribute to your noise exposure levels. Stage 1 is to attempt to shut the noise down at the source. Call our help desk to discuss your project with a sound consultant and we’ll work with you to come up with a customized & cost-effective solution.

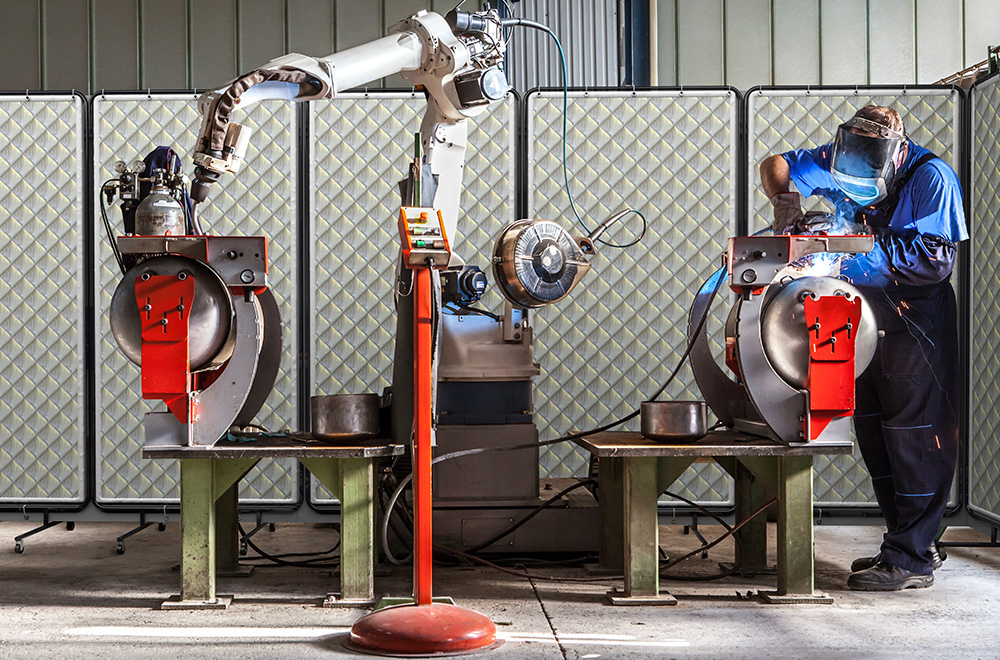

2. Isolate Your Work Space

Oftentimes, our industrial noise control and acoustics projects cannot build blanket enclosure systems around their machinery without interrupting the processes being performed. In this case, step back from the machine, take the same sound barrier blankets that we make our enclosures with, and build acoustic fence walls that isolate the workspace from the rest of your plant by containing it to a limited area. This is stage 2 in your industrial noise control quest. Portable Sound Screens are an excellent way to keep the noise contained by isolating a loud workspace, protecting adjacent employee workstations from your most aggressive noise sources. Once the noise is separated and contained, then move on to stage 3: Reduce the echoes & reverberation.

3. Reduce Your Echo

Finally, with or without any kind of sound barrier blanket system, controlling the exposure to noise in your plant or manufacturing space will also rely on introducing a set of wall-mounted panels or ceiling-mounted baffles. These industrial sound absorbing treatments are designed to capture and convert the echoes from your space. Echoes lead to a spike in dB levels as sound sources combine, and controlling them with our sound absorbing industrial acoustic panels & baffles will help decrease your sound pressure levels. Industrial noise control is a staging process, and this is stage 3. Noise levels in your factory will spike due to echoes that are not captured and converted to heat energy. But please note, echo control yields smaller noise reduction values back. It is far more effective to block the noise at its source than to absorb the noise along a reflective path. Use a combination of these industrial noise control methods & products to achieve optimum sound attenuation results.